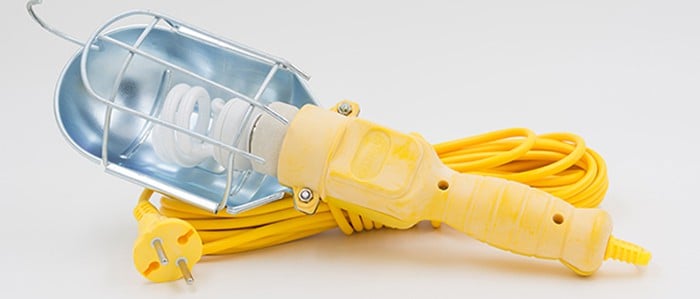

For many construction and contracting projects, portable lighting is essential to viewing work. The type of lighting used must be safe for the location, especially if there are also hazardous or flammable materials in the area.

As with any type of electrical equipment, always follow the manufacturer’s instructions. The potential for an explosion and/or fire due to the combination of a flammable atmosphere, and improper use of heat producing portable lighting, makes it essential to understand the regulations, codes and classifications before you use any safety lighting or other electrical tools.

With proper safety precautions, portable lighting can be used effectively to enhance workplace safety and get the job done. Here are a few safety tips to keep in mind when using portable lighting in a hazardous location:

- Ensure the light has been tested and approved by recognized agencies such as UL, ULC, FM, NFPA, and CSA. This shows that it complies with recognized safety standards.

- Use lights only in the locations for which they are intended.

- Do not use non-explosion proof trouble lights where there is a risk of contact with gasoline or other flammable liquids or vapours.

- When portable lights are used near a fuel source where splashing or explosive atmospheres occur, only use units specifically designed for use in that hazardous situation. Bulb surface temperatures can approach 260°C (500°F) providing a potential ignition source in those conditions. It’s also possible that any of the trouble light components, connections, switches, etc., may result in electrical arcs and provide potential ignition sources.

- Trouble lights are not intended to be a permanent light source.

- Hazardous location flashlights are an excellent alternative to trouble lights.